The smart Trick of American Plastics That Nobody is Discussing

Wiki Article

American Plastics Things To Know Before You Buy

Table of ContentsNot known Facts About American PlasticsLittle Known Questions About American Plastics.Everything about American PlasticsThe Ultimate Guide To American PlasticsWhat Does American Plastics Mean?How American Plastics can Save You Time, Stress, and Money.

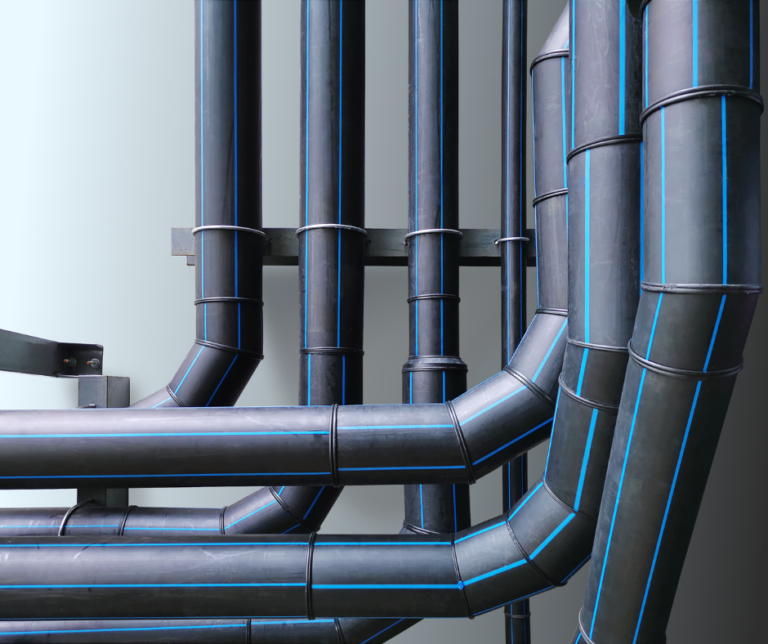

This may consist of securing pipes from extreme temperature levels, avoiding exposure to chemicals or corrosive materials, and implementing appropriate support and securing to stop sagging or movement. Here are solution to some often asked inquiries pertaining to HDPE pipe PSI rankings: The maximum PSI rating for HDPE pipes can vary depending upon variables such as diameter, wall surface density, and product make-up.No, it is not suggested to use a lower PSI-rated HDPE pipe for a higher-pressure application. Doing so may lead to pipe failing, leakages, or other safety dangers.

You can confirm the PSI ranking of an HDPE pipeline by checking the supplier's paperwork and accreditation. Respectable manufacturers give precise and trusted information concerning the PSI rating of their pipes.

Excitement About American Plastics

Stay informed concerning the most up to date developments in the industry to leverage the innovations that can better boost your tasks. With this detailed overview at hand, you are fully equipped to make educated choices and accomplish successful results. The Great Pyramid of Giza The Hanging Gardens of Babylon No matches were located.All metropolitan water systems include flowing water. HDPE (PE4710) DR 17 pipeline has a static stress rating for water of 125 psig. The working stress score (WPR) is based upon actual system needs and is a, that is, a pressure rating for pipeline with streaming water.

At an everyday reoccuring average circulation surge velocity of 5 fps and at 80oF, the functioning pressure ranking of HDPE (PE4710) DR 17 pipeline is also125 psig; similarly, the functioning stress score for PVC DR 18 is 120 psig per AWWA C900-07, Formula 4. As such, PE 4710 has a greater working pressure score than PVC at these typical problems.

Some Known Incorrect Statements About American Plastics

This associates with savings in replacement expenses for generations to come. Yes, HDPE pipe, as a result of its density being slightly less than water, will certainly drift also when packed with water. When it is wanted to guarantee flotation protection of the line, numerous types of collars, saddles, and strap-on flotation tools are readily available.Screw-anchors are a sensible option. Whenever possible, an underwater pipe ought to be installed in a trench with protective gravel cover. Describe Phase 10 of the PPI Handbook of Polyethylene Pipe, 2nd ed. HDPE pipeline's regular operating temperature level variety is from -40 oF (-400 C) to 140oF (60oC) although some items might be stress rated for service as high as 180oF (82oC).

Consult with the pipe manufacturer for details on applications. The within surface area of HDPE pipe is lacking any type of roughness which positions it in the "smooth pipe" classification, a classification that leads to the most affordable resistance to fluid flow. For water applications, HDPE pipeline's Hazen and Williams C aspect for style is 150 and does not alter in time.

The American Plastics Ideas

Thorough discussion of this subject can be discovered in Phase 9 of PPI's Handbook of Polyethylene Pipeline, 2nd ed. The pipeline recovery industry has actually adopted "pipe bursting" as the name of the procedure of bursting fragile pipes (e.g., cast iron, clay, and so on).Prep work of the host pipeline to obtain the HDPE pipe is achieved with a cone shaped head in both rupturing and splitting processes. Refer to PPI Handbook of Polyethylene Pipe, 2nd ed., Chp 16.

The smart Trick of American Plastics That Nobody is Talking About

3), and others. Hydrocarbons do not deteriorate polyethylene however can diffuse with the wall surface of HDPE pipeline in locations of gross contamination. The outside call might affect saddle fusion connections, thus, after HDPE pipes have been exposed to blatantly infected soils, mechanical links might be favored. On top of that, while steps need to be taken to restrict the impact of hydrocarbon permeation, the large majority of HDPE pipes installations will never be affected by this issue. hdpe pipe fittings Midland TX.In-depth discussion of this topic can be found in Chapter 9 of PPI's Handbook of Polyethylene Pipeline, second ed. Publications readily available from the pipeline maker may also cover this subject. Yes, pipeline bursting has actually confirmed to be a really important ways of pipeline recovery. The pipeline rehabilitation sector has taken on "pipe bursting" as the name of the process of fracturing breakable pipes (e - https://swaay.com/u/danecoffman79701/about/.g., cast iron, clay, etc).

Prep work of the host pipeline to get the HDPE pipe is achieved with a cone designed head in both rupturing and splitting processes. Refer to PPI Handbook of Polyethylene Pipe, 2nd ed., Chp 16. HDPE is a ductile material and has extraordinary effect stamina. HDPE's remarkable effect stamina gives a piping system that is near unsusceptible effect damage and to damage from incorrect tapping.

HDPE pipelines are field examined and confirmed to be great site impact difficult. AWWA has attended to issues relating to hydrocarbon permeation by including a permeation declaration in all of its pipeline requirements consisting of requirements for polyethylene (PE) (C901-08 p. 6, C906-07 p. 6), polyvinyl chloride (PVC) (C900-07 p. 6, C905-97 p. 3), steel (C200-05, p.

More About American Plastics

3), and others. Hydrocarbons do not break down polyethylene however can diffuse with the wall surface of HDPE pipe in areas of gross contamination. The external call may affect saddle combination links, therefore, after HDPE pipes have actually been exposed to blatantly contaminated soils, mechanical links might be chosen. On top of that, while measures require to be taken to limit the effect of hydrocarbon permeation, the substantial bulk of HDPE water pipe setups will certainly never be impacted by this issue. https://slides.com/americanplastics.Report this wiki page